3D Printing

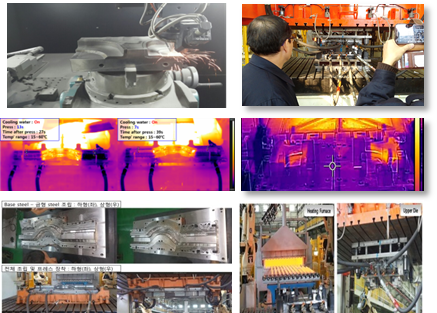

Cooling channel For Hot Stamping

· Joint technology development through Euro Star 2 Global Project.

– Republic of Korea: IJS and 3 other companies, Lab

– Spain: ROVALMA

· Enables high level of cooling channel forming

· Maximizes cooling efficiency due to low limit on channel designing process. (40% lower than the average temperature)

· 40% shorter cycle time at manufacturing stage.

Trim die

· Making Laminated die without heat treatment or coating of the trimming blades

· Shorten production time by 30%, Cut down costs by 30%, equal or higher performance.

· Able to trim ultra high strength steel. (780MPa)

· Test die successfully completed 30,000 press.

· Achieved performance standard for mass production; 5,000press.

· Ready to be implemented for mass production in 2018.